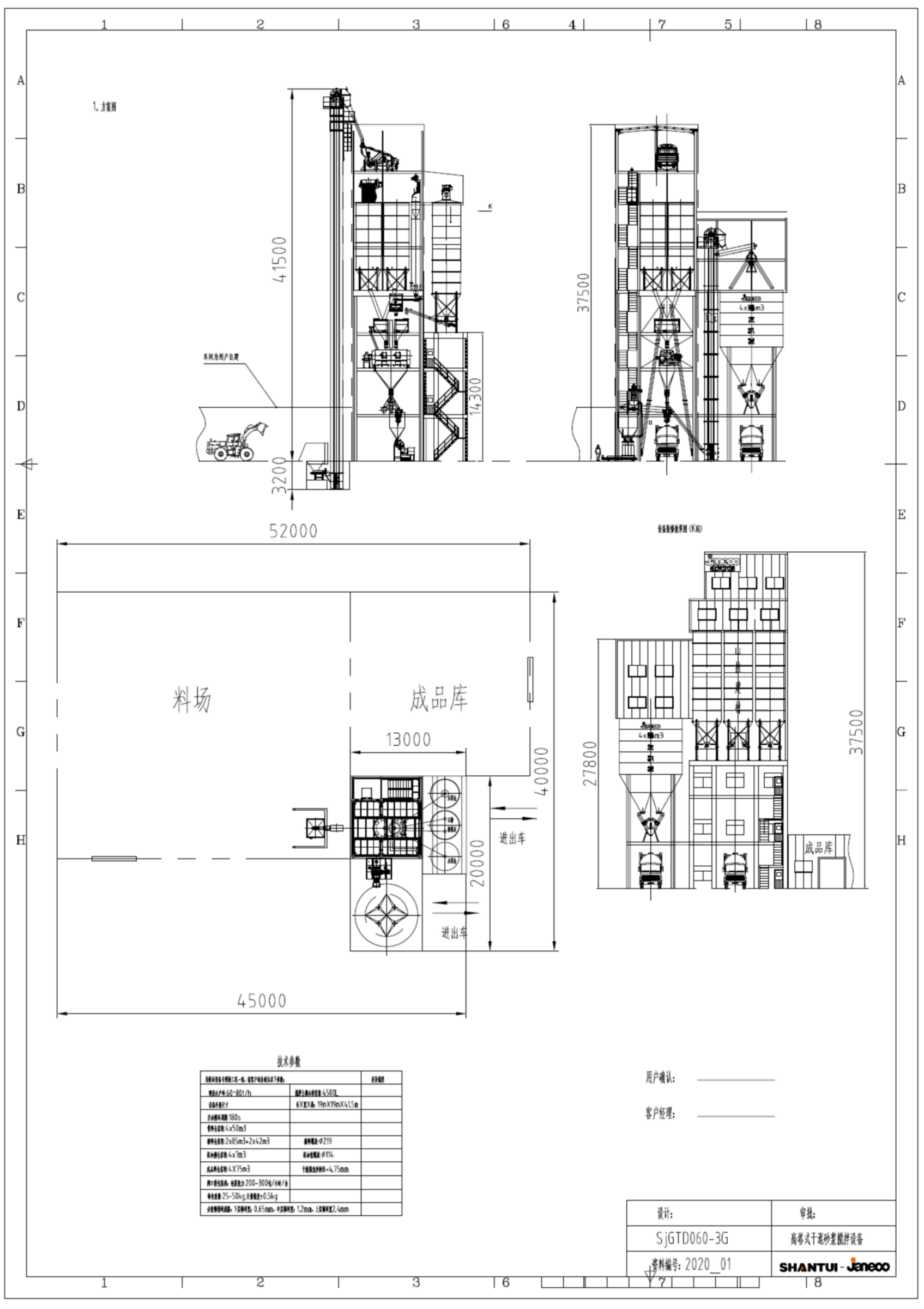

SjGTD060-3G Tower Tipe garing Mortir Batching Plant

spésifikasi utama

1.spésifikasi utama

produktivitas teoritis 60-80t / h

Adun SjGD4500-5B

agrégat ngukur akurasi ± 2%

Akurasi ukur semén ± 1%

akurasi ukur aditif ± 0,5%

Keusik silo volume 4X50m3

Silo semén volume 2X85m3+2X42m3

Silo semén volume 2X85m3+2X42m3

Kapasitas packing 200-300bags / h / set

Kapasitas packing 200-300bags / h / set

1.Keusik lift lift

| Tipe | TB60 |

| Laju kerekan | 1.1m/s |

| Kapasitas téoritis | 60m3/h |

| kakuatan motor | 18,5 kW |

2.Pasir batching parasut pipe

| diaméterna chute | 323 mm |

3.Semén batching screw conveyor

| diaméterna screw | 219 mm |

| kapasitas | 60t/jam |

| kakuatan motor | 7,5KW |

4.Fly lebu batching screw conveyor

| diaméterna screw | 219 mm |

| kapasitas | 60t/jam |

| kakuatan motor | 7,5 kW |

5. Thickening bubuk batching screw conveyor

| diaméterna screw | 219 mm |

| kapasitas | 60t/jam |

| kakuatan motor | 7,5 kW |

6. agrégat ukur Hopper

| ngetik | skala éléktronik |

| nilai Max | 4000 kg |

| akurasi | ± 2% |

7. hopper ukur semén

| ngetik | skala éléktronik |

| nilai Max | 2000 kg |

| akurasi | ± 1% |

8.aditif ukur Hopper

| ngetik | skala éléktronik |

| nilai Max | 150 kg |

| akurasi | ± 0,5% |

9.sistem mixer

| Adun | SjGD4500-5B |

| kakuatan motor | 90KW |

| kakuatan sabeulah | 4x5,5 KW |

10.impeller feeder

| diameter | 400 mm |

| kakuatan motor | 3KW |

| kapasitas | 50m3/h |

11.mesin bungkusan

| kapasitas packing | 200 ~ 300 kantong / h / set |

| unggal beurat | 25 ~ 50 Kg |

12.mesin sabuk

| mesin sabuk | 2KW |

13.produksi screw conveyor

| ngetik | GX500 |

| kapasitas | 70m3/jam |

| kakuatan motor | kakuatan motor |

14 mesin bulk

15.produksi kerekan lift16.2 produksi screw conveyor 217.sistem listrik19.sistem listrik

Sistim ieu Powered by ac 380V jeung 50Hz tilu-fase opat (lima) sistem kawat.

20.kontrol komputer

kontrol komputer

21.waktu siklus

otomatis: 180s

| kapasitas | 100t / jam |

| jarak fléksibel of discharging gate | 1200 mm |

| kakuatan motor | 0,55 kW |

| kakuatan kipas filter | 2,2 kW |

| ngetik | TB110 |

| laju kerekan | 1.1m/s |

| kapasitas | 110m3/jam |

| kakuatan motor | 22 kW |

| diaméterna screw | GX500 |

| kapasitas | 70m3/jam |

| kakuatan motor | 7,5KW |

| kakuatan compressor hawa | 37 kW |

| tekanan | 7,5KW |

Katerangan

Sjgtd060-3g alat batching mortir garing adopts struktur munara, kalawan produktivitas badag, hemat energi jeung perlindungan lingkungan, ciri stabil sarta dipercaya, utamana dipaké pikeun Pergaulan mortir garing biasa.

Parabot utama adopts struktur munara, kalawan 4 silos keusik, 4 silos bubuk, 4 silos aditif jeung 4 silos produk rengse.Keusik pikeun pamakéan kawat biasa diangkat ku mesin LIPI jeung disimpen dina bin keusik sanggeus screening.Powder gradasi dikirimkeun ka bin bubuk ku bulk tanker.The aditif diangkat ka storehouse aditif ku alat ngangkat listrik sarta nempatkeun kana storehouse aditif sacara manual .

Keusik adopts ngageser pipe batching, bahan bubuk, aditif ngadopsi spiral conveyor batching.

LIPI ukur nganggo skala éléktronik pikeun ngukur, anu gaduh akurasi pangukuran anu luhur sareng kasalahan leutik.

Sistim kontrol adopts manual tur otomatis control.The Sistim boga sampurna timer Ngonci na antar-Ngonci fungsi pikeun mastikeun operasi akurat jeung dipercaya tina sistem, sarta boga deteksi sesar umum jeung fungsi alarm.

Konfigurasi

| parabot baku | ||||

| No. | Katerangan | Barang | Qty | Nyarios |

| 1 | alat kerekan keusik garing | 1 |

| |

| lift(42m) | 1 | |||

| tangga jeung platform | 1 | |||

| chute dahar jeung discharging | 1 | |||

| 2 | alat layar gradasi | 1 |

| |

| 3 lapisan layar geter (2x3.6KW) handap: 0.65mm, pertengahan: 1.2mm, luhur 2.4mm | 1 | |||

| pipa nyulam | 1 | |||

| 3 | saringan pasir silo | 1 |

| |

| pipa saluran φ325 | 4 | |||

| klep pneumatik (DN300) | 4 | |||

| ngasupkeun klep | 4 | |||

| pulsa deui siram filter HMC48 | 1 | |||

| 4 | skala pasir | 1 |

| |

| nilai maksimum 4000kg | 1 | |||

| sensor tekanan | 3 | |||

| sendi sénsor | 3 | |||

| klep pneumatik (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | skala semén | 1 |

| |

| nilai maksimum 2000kg | 1 | |||

| sensor tekanan | 3 | |||

| sendi sénsor | 3 | |||

| klep pneumatik (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 6 | skala aditif | 1 |

| |

| nilai maksimum 150kg | 1 | |||

| sensor tekanan | 3 | |||

| klep pneumatik (DN200) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 7 | alat dahar manual | 1 |

| |

| hopper dahar jeung panutup | 1 | |||

| klep pneumatik (DN200) | 1 | |||

| 8 | saringan aditif | 1 |

| |

| klep pneumatik (DN150) | 4 | |||

| saringan silo aditif | 1 | |||

| 9 | sistem campur kode (V: 4500L) | 1 |

| |

| alat nyetir 90KW | 1 | |||

| alat keur nyampur | 1 | |||

| speed tinggi Rotary scraper 5.5KW | 4 | |||

| gerbang discharging | 1 | |||

| tank nyampur | 1 | |||

| alat sampel | 1 | |||

| 10 | Hopper utama sareng bulk | 1 |

| |

| awak hopper | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| feeder impelled | 1 | |||

| pneumatic 4 fase | 1 | |||

| méteran tingkat usaha Rotary ILTC0 | 1 | |||

| mesin bulk | 1 | |||

| 11 | mesin packing produksi |

|

| |

| awak hopper | 1 | |||

| méteran tingkat usaha Rotary ILTC0 | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| 2 kaluar mesin packing | 1 | |||

| mesin sabuk produksi (B = 650mm, 2.2kw) | 1 | |||

| 12 | hoist produksi jeung distributor | 1 |

| |

| lift (24m, 15kw) | 1 | |||

| tangga jeung platform | 1 | |||

| chute dahar jeung discharging | 1 | |||

| rojongan screw | 1 | |||

| Rotary distrubuter 0,75KW | 1 | |||

| 13 | bulk produksi | 1 |

| |

| klep sisipan pneumatic | 4 | |||

| klep pneumatik (DN300) | 4 | |||

| hopper tansition | 1 | |||

| mesin bulk | 1 | |||

| 14 | packing alat saringan | 1 |

| |

| pulsa deui siram filter (1.5kw) | 1 | |||

| pipa saringan | 1 | |||

| klep manual (DN150) | 1 | |||

| 15 | Sistim pneumatic | 1 |

| |

| compressor hawa | 1 | |||

| tank gudang 1m3 | 1 | |||

| tank gudang 0,3m3 | 2 | |||

| saringan utama | 1 | |||

| pengering | 1 | |||

| mendi | 1 | |||

| 16 | sistem kontrol | 1 |

| |

| komputer industri | 2 | |||

| software | 2 | |||

| komponén listrik | 1 | |||

| 19 monitor LED | 2 | |||

| panyitak | 1 | |||

| sasayogian tanaga | 1 | |||

| méja operasi | 1 | |||

| kabinét listrik | 1 | |||

| kawat jeung kabel | 1 | |||

| 17 | sistem panjagaan | 1 |

| |

| kaméra warna | 4 | |||

| lénsa cemera | 4 | |||

| monitor LED | 1 | |||

| nyelapkeun DV | 1 | |||

| 18 | Struktur baja utama |

|

| |

| sasis | 1 | |||

| tangga | 1 | |||

| rojongan | 1 | |||

| pangiriman gudang jeung hiasan luar | ||||

| 19 | semén screw conveyor | φ219X6000 mm | 2 |

|

| 20 | semén screw conveyor | φ219X5000 mm | 2 |

|

| 21 | 机 aditif screw conveyor | φ114 x 3000 mm | 2 |

|

| 22 | aditif screw conveyor | φ114 x 2000 mm | 2 |

|

| 23 | produksi screw conveyor | GX500-4500 | 1 |

|

| 24 | produksi screw conveyor | GX500-2500 | 1 |

|

| 25 | Silo neundeun keusik | 4 |

| |

| V: 50m3 | 4 | |||

| klep manual | 4 | |||

| méteran tingkat Rotary | 8 | |||

| 26 | silo neundeun semén | 2 |

| |

| v:85m3 | 2 | |||

| pemutus lengkung | 2 | |||

| klep manual (DN300) | 2 | |||

| méteran tingkat Rotary | 4 | |||

| klep aman | 2 | |||

| silo luhur pulsa deui siram filter | 2 | |||

| 27 | silo neundeun semén | 1 |

| |

| V: 2x42m3, silo insulasi | 1 | |||

| pemutus lengkung | 2 | |||

| klep manual (DN300) | 2 | |||

| méteran tingkat Rotary | 4 | |||

| klep aman | 2 | |||

| silo luhur pulsa deui siram filter | 2 | |||

| 28 | silo gudang produksi | 1 |

| |

| V: 4x75m3, silo insulasi | 1 | |||

| pulsa deui siram filter (1.5kw) | 1 | |||

| pemutus lengkung | 4 | |||

| klep manual | 4 | |||

| méteran tingkat Rotary | 8 | |||

| 29 | silo aditif | 4 |

| |

| v:7m3 | 4 | |||

| méteran tingkat Rotary | 4 | |||

| vibrator MVE 60/3 | 4 | |||

| klep manual (DN300) | 4 | |||

| 30 | alat kerekan listrik | 1 |

| |

| kerekan listrik | 1 | |||

| rel, kandang | 1 | |||

| 31 | hiasan | hiasan 1500m2(0.5mm) | 1 |

|

| pigura awak | 1 | |||